Create standards and quality in injection molding.

Accelerate manufacturing with this sensor.

In-mold Measuring System

MOLD MARSHALLING SYSTEM

System to measure the behavior of resin in injection molding mold

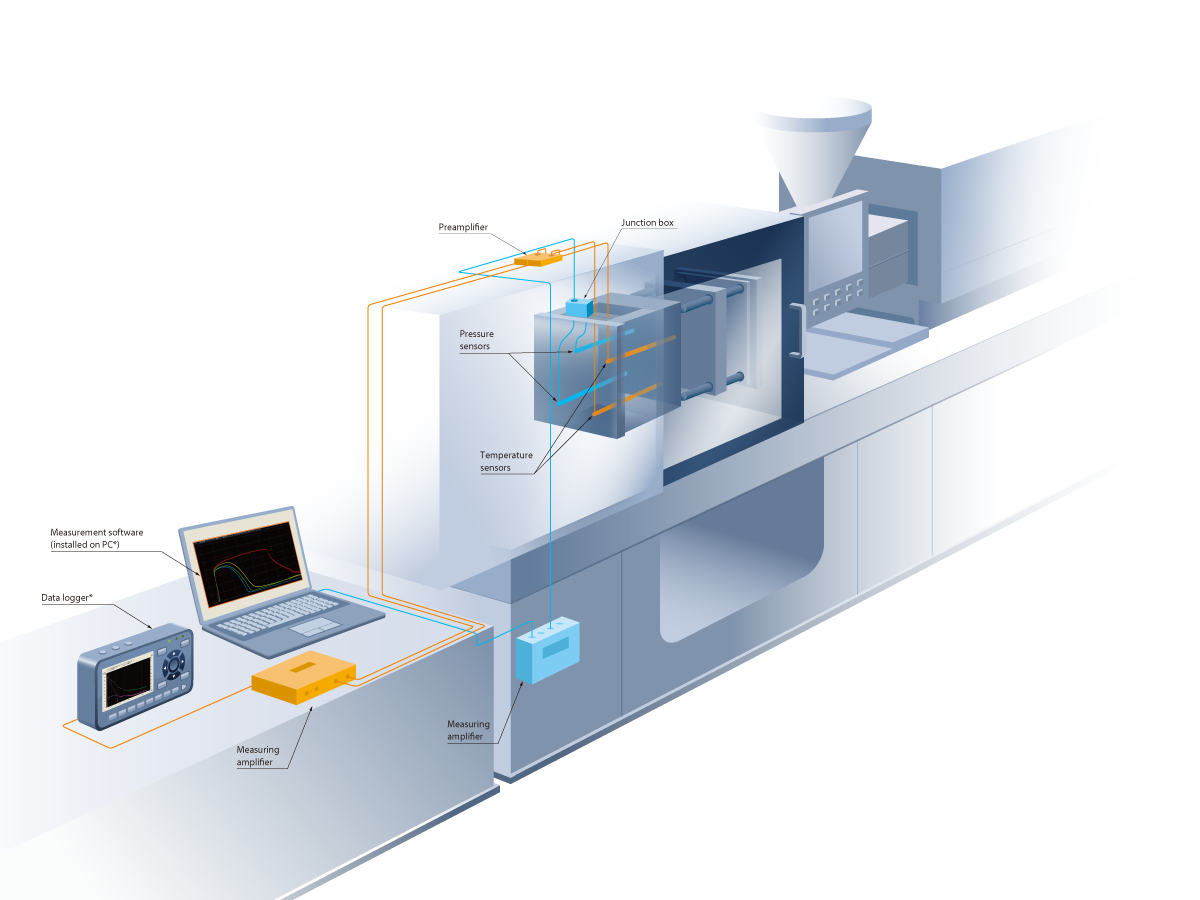

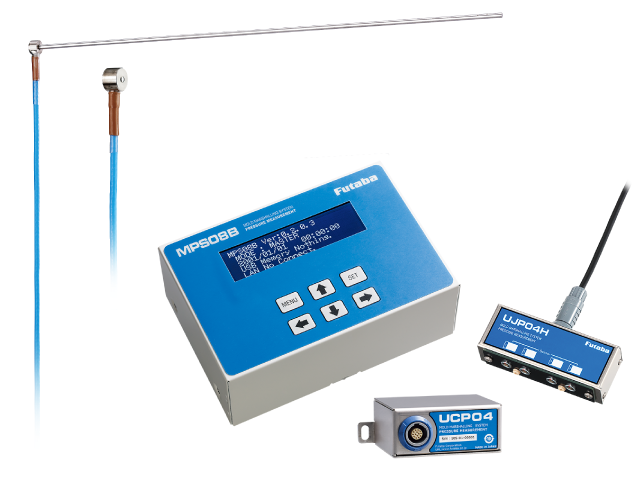

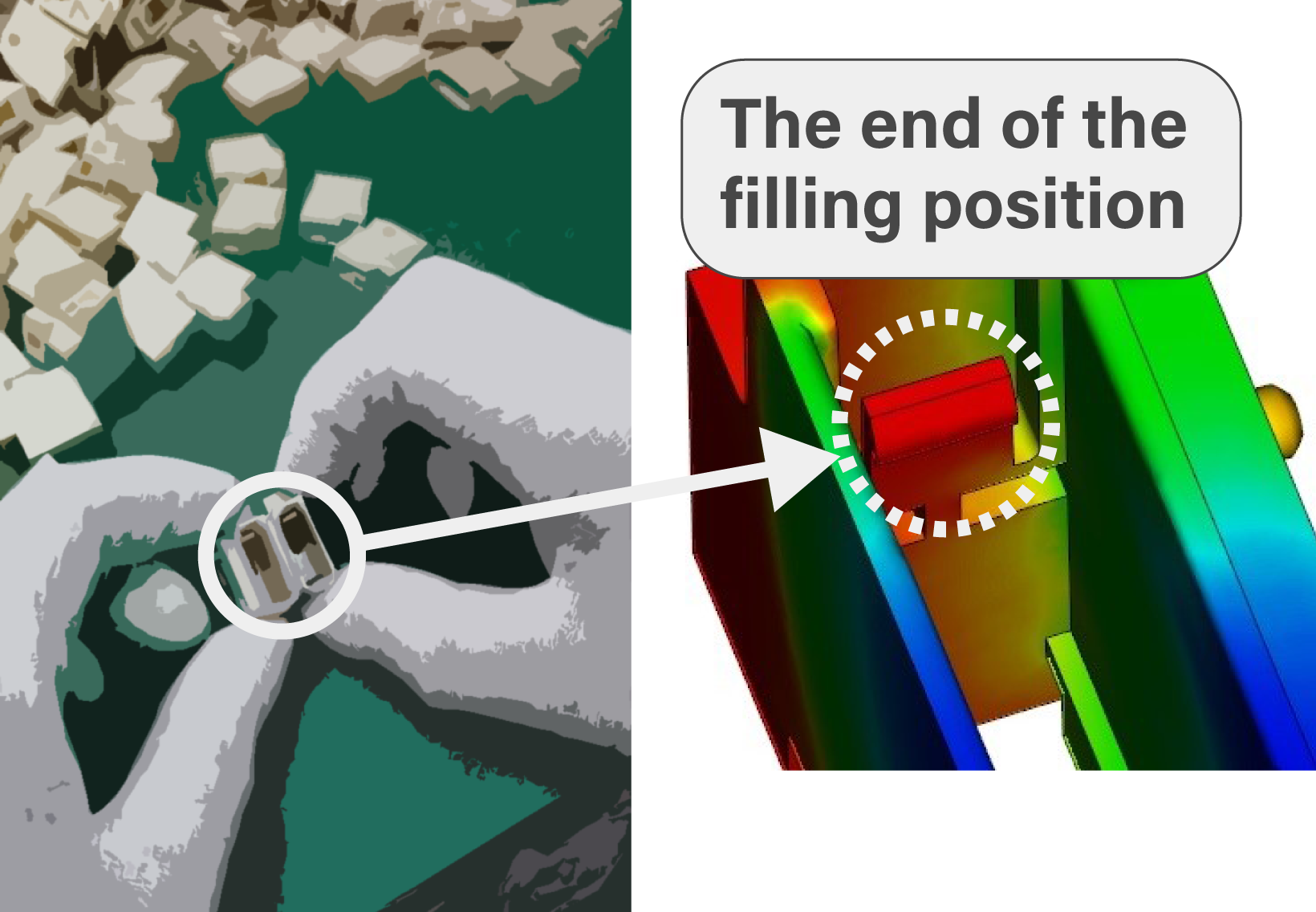

MOLD MARSHALLING SYSTEM is a measurement system for injection molding that converts the behavior of the resin in the mold, which has conventionally been a black box, into a signal or voltage and outputs it in real time with waveforms to a PC or various measurement instruments by means of a sensor and a dedicated amplifier installed inside the mold.

What MOLD MARSHALLING SYSTEM can achieve

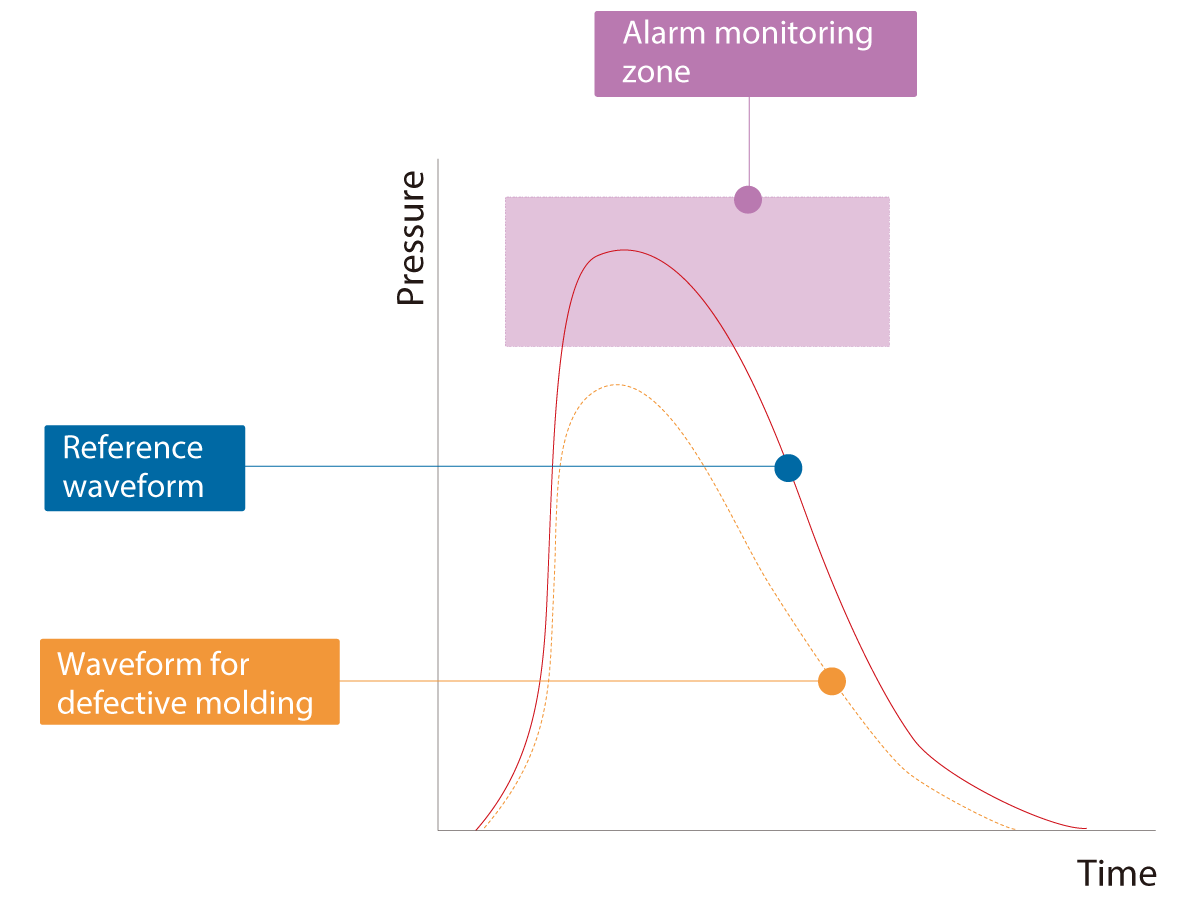

01 Judges the injection molding quality by waveform.

By setting an alarm monitoring zone to the waveform generated with good product quality, it is possible to detect molding defects such as short shot and overpack. By outputting alarm signals to an external device, it is also possible to automatically sort defective products.

02 Digitalizes engineers’ hunches and knacks.

MOLD MARSHALLING SYSTEM can quantitatively analyze the hunches and knacks, for which engineers have been conventionally relied upon, by digitalizing it. It is possible to measure major injection molding items, such as in-mold pressure, resin temperature, mold temperature, and flow rate.

03 Reproduces the “made-in-Japan” quality even in overseas production.

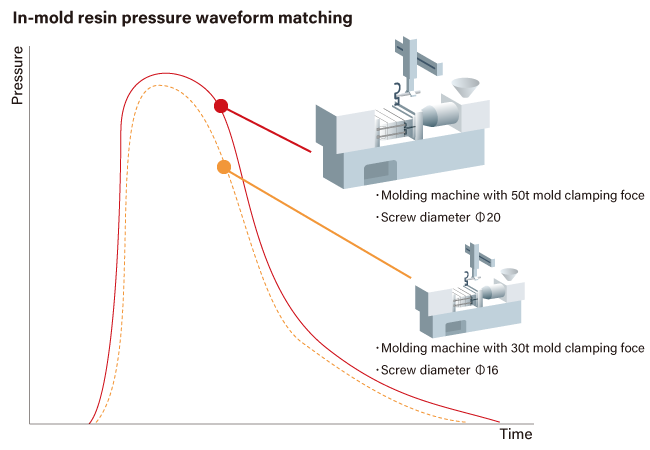

By setting the molding conditions in such a way that the measurement waveform overlaps with the waveform generated with good product quality, it is possible to perform injection with the same quality even in a different environment (machine, factory, country, etc.).

Why MOLD MARSHALLING SYSTEM?

01 In-mold sensing can be introduced at low cost.

The MOLD MARSHALLING SYSTEM is offered at an affordable price to make in-mold sensing more accessible to customers. Therefore, it can be used not only for research and development purposes but also for mass production lines.

View product brochure

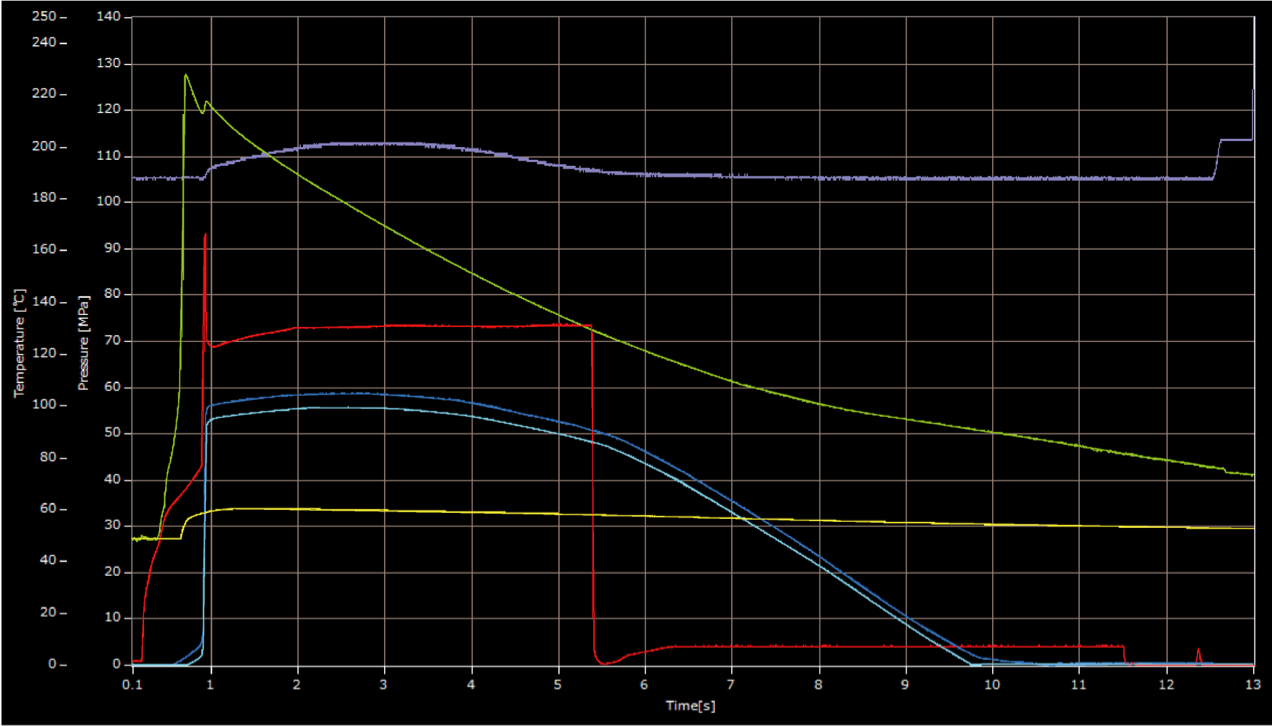

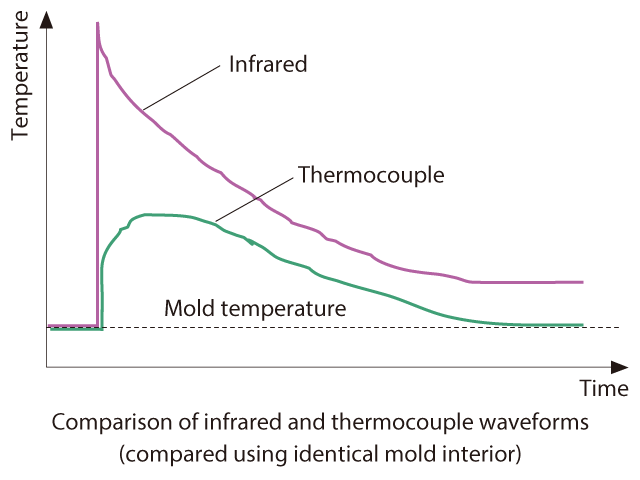

02 High-speed response: Measurements in 8ms (Futaba resin temperature sensor)

To accurately measure the ever-changing resin temperature in the mold, the responsiveness of the sensor is important. The resin temperature sensor of the 'optical fiber infrared method' developed by our company has reached a response time of 8 ms and can accurately measure the resin temperature in the mold from the resin inflow to the mold opening.

*The 8 ms response time is the measured value at 63.2% response.

View resin temperature sensors

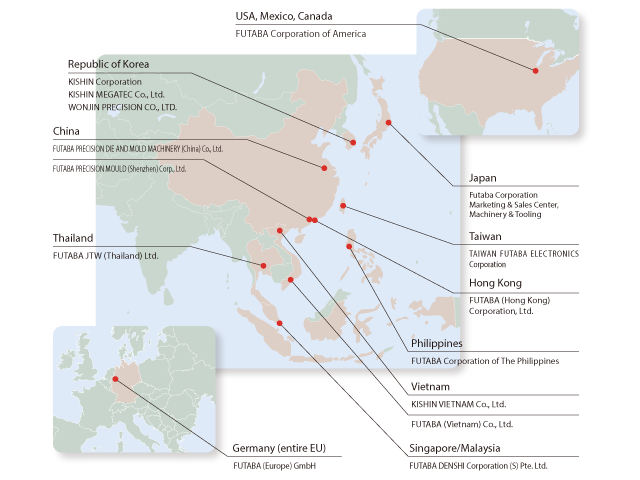

03 Have global track records

MOLD MARSHALLING SYSTEM has been sold since 1999 and has been introduced to many customers both in Japan and abroad. In addition to our extensive sales and support in Japan, we also have sales offices overseas and will do our best to support the introduction of our products overseas.

Inquiry

Case Studies

-

“Succeeded in reducing inspection workload, resulting in an annual savings of 2.3 million yen ”

- KAWACHO Co., Ltd. -

- ・Defected products of short shots were outflowed.

- ・The company strengthened its inspection system,but this required a great deal of inspection time.

- ・The problem could not be solved by image inspection equipment or by the molding machine monitoring function.

- ・MMS has solved the problem of reducing inspection workload.

-

“Visualization of manufacturing process, reform under the site initiative”

- Tamagawa Microtep Co., Ltd. -

- ・MOLD MARSHALLING SYSTEM has been introduced to identify the causes of defects.

- ・Visualization of the causes of defects

- ・Modification of mold based on data

- ・Defect prediction and visualization of mold maintenance timing through utilization of MT method